As a leading German luxury automaker showcases the multiple benefits of modular assembly, automakers are leveraging transformative digital technologies that accommodate the demand for mass personalization.

It is being seen as the next big, digitally-enabled leap in automotive manufacturing – modular assembly. Audi recently announced that it would be leveraging the modular assembly concept to support the development of more agile and efficient production and accommodate the rising demand for personalization at scale.

Audi’s smart production systems eschew the rigid linearity of the traditional assembly line approach to embrace simplified, streamlined, highly interconnected cycle-independent production systems. This innovative approach is anticipated to yield time and resource efficiencies, enhance productivity, remove location constraints, reduce failure rates, improve product offerings, and support flexibility in product manufacturing at a time individualization is on the ascendant. This will mean vehicles built to varied specifications can be designed, developed, and delivered to the customer faster than ever before.

Underpinning Audi’s new production system is a raft of cutting-edge technologies, including virtual reality (VR) technologies, augmented reality (AR), artificial intelligence (AI), machine learning (ML), and digital twinning (DT) concepts.

For more information on how advanced technologies are creating the factories of the future, please access our research report: Growth Opportunities for Digital Twins in Global Mobility or contact [email protected] for information on a private briefing.

Our Perspective

“Mass personalization has become inevitable in the automotive sector due to the unique tastes and preferences of each consumer. There would ideally be as many variants of the automobile as there are customers. This can be efficiently achieved by engaging a combination of several transformative digital technologies like Digital Twins, automated guided vehicles, AI driven robots, and Machine Vision Systems, along with data analytics and virtual reality tools, which Audi seems to have rightly employed.”— Sandhya Jesu, Industry Analyst, Mobility Practice at Frost & Sullivan.

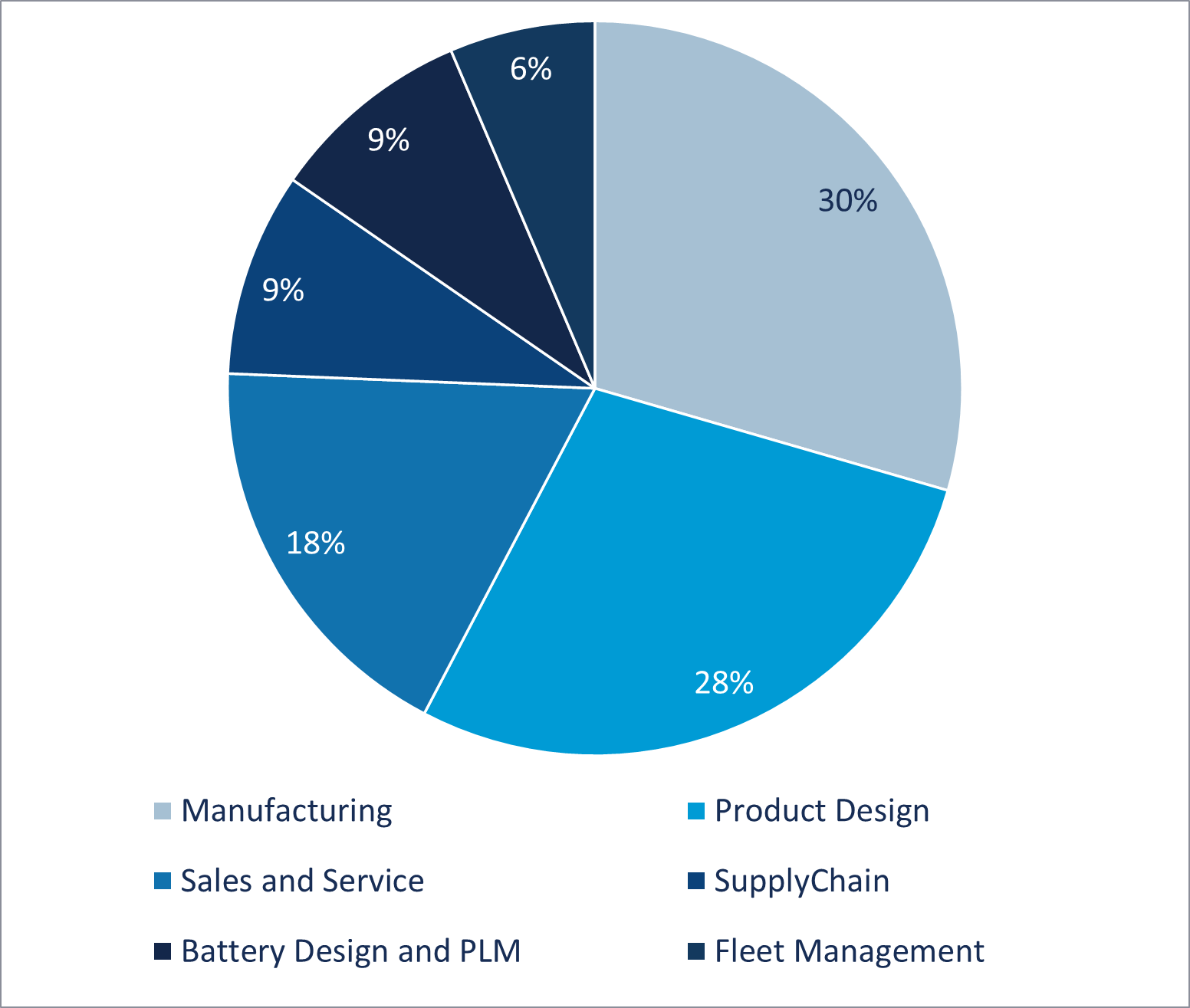

It is now increasingly evident that AI and data analytics are on course to disrupt the automotive ecosystem. The adoption of digital twinning (DT) – a disruptive and transformative concept with data at its core – has accelerated in virtually every aspect of the automotive area from product design and testing to supply chain, sales and services to manufacturing.

Digital Twinning in Mobility: Market Share Estimates by Functional Area, Global, 2021

- Major chunk of the DT contracts in automotive are in manufacturing and product design.

- Almost every major OEM has already implemented DT in manufacturing.

- Going forward, the OEMs would move towards DTs of higher resolutions and wider integration of the DTs

In terms of functional arenas, we are seeing almost every major OEM implementing DT in manufacturing. Among DT applications in the manufacturing space include performance optimization, predictive maintenance and scheduling (PMS), remote monitoring and control (RMC), zero-hazard shop floor, inventory management, and mass personalization.

Intelligent DT promises a cascade of benefits for OEMs of which one of the most crucial will be its ability to support mass personalization. This will be predicated on the capability to create customized components to resolve needs/issues using DT-derived insights, generative design techniques, and 3D printing. Beyond that, integration with AI will further advance intelligent DT, enabling immediate identification of anomalies and optimal decision making. DT will be key to driving the adoption of 3D printing in manufacturing.

Multiple Applications of DT

As part of our research to understand how the factories of the future are developing, we did a case study analysis of several leading OEMs and their engagement with DT. For instance, we found that Audi visualizes the use of DT in product design and has released digital twins for some of its high-end cars, with Porsche on track to release digital twins for some of its upcoming models. Audi and Skoda have implemented DT to add capacity and enhance their production plants.

Audi’s Ingolstadt body shop employs LayAR, leveraging DT and AR. A digital twin of the production floor uses AR, while DT is used to facilitate logistics planning. Resultant outcomes range from the improved ability of logistics planners to work simultaneously from different locations to users being able to touch and move objects. Moreover, using NavVis and Microsoft HoloLens, Audi has created a digital twin of its Neckarsulm production facility, enabling an exact representation of the real space.

In addition, Audi integrates data from its digital twin to design and test new models and uses Epic Games’ Unreal Engine to exhibit the model. This has allowed the company to showcase its designs virtually in a highly realistic and interactive manner before production.

Other OEMs have also successfully embraced DT in multiple arenas. For instance, BMW has digitally twinned its 31 production factories, terming them the ‘factories of the future’. It has leveraged holistic digital twin environments (DTEs) to support a wide range of AI-enabled operations, such as virtual product design, predictive maintenance, and autonomous robots. It has even developed a digital version of humans to improve workplace ergonomics.

GM has applied DT in the core areas of product design, manufacturing, and battery analytics. By 2025, VW intends to spend about $3.6 billion to build the largest digital ecosystem in the automotive industry. Furthermore, in partnership with Siemens, it is seeking to identify how DT can boost production line efficiencies.

The Mercedes-Benz Group and Daimler Truck North America (NA) have also made significant strides towards innovative, technology-led production. Mercedes uses DT to enhance its design and manufacturing capabilities, racing strategies, and digital cockpit offerings to customers. Daimler is looking to integrate DT into the company DNA, maximizing its use in areas spanning product design, manufacturing, sales, and customer experience.

Ford looks beyond the vehicle, deploying DT to create twinning alleyways and generate analytics for mobility as a service (MaaS). Meanwhile, Hyundai’s highly futuristic and experimental focus – it is also the first OEM to employ the metaverse – draws heavily on synergies with DT. Volvo, which has been one of the forerunners in deploying blockchain in the supply chain, is evaluating DT initiatives in the manufacturing and the supply chain.

In short, leading automakers are looking at innovative, technology-led concepts—across production design & development, manufacturing, sales and services, supply chain, electric vehicle battery design and product lifecycle management (PLM)—to boost efficiencies, strengthen resilience, and drive disruptive innovation.

Schedule your Growth Pipeline Dialog™ with the Frost & Sullivan team to form a strategy and act upon growth opportunities: https://frost.ly/60o.