Algae are versatile organisms that can grow in a variety of environments including fresh, brackish, sea, and waste water. Coastal and lakeside communities have cultivated algae for centuries and have known its utility as a food source and fertilizer, and its applicability in pest control and pollution control. However, prior to the 20th century, most algae cultivation was limited to small-scale operations; it remained an untapped resource among the wider global population. Research into algae and its use as a source of fuel, chemical feedstock, and pharmaceuticals in the 1940s changed this, and brought about the adoption of large-scale cultivation methods in the latter half of the century.

Research and commercial interests today are primarily focussed on the use of algae as biofuel feedstock and as a functional food. Nevertheless, research into algae-based wastewater treatment has shown immense potential, especially when coupled with existing biological treatment systems. Algal-bacterial wastewater treatment systems have significant benefits in the form of carbon-dioxide abatement, methane emission reduction, energy savings, and productive use of wastewater and barren land. Its market adoption and success, however, is held back by difficulties in the effective utilization of algal biomass. This market insight explores the issues with current wastewater treatment systems and the potential benefits of an integrated algal-biological system.

CURRENT WASTEWATER TREATMENT METHODS

The fundamental concepts of contemporary wastewater treatment were discovered in the early 20th century through the study of aerobic and anaerobic bacteria that break down and oxidize organic compounds. Since then, bacteria-based biological treatment has been the norm for municipal wastewater, with aerobic treatment systems being prevalent. This is primarily due to the versatility of aerobic bacteria, which can treat wastewater of varying quality and composition, achieve faster and more effective breakdown of organics when compared with anaerobic bacteria, and remove nutrients such as nitrogen, phosphorous, and potassium from wastewater.

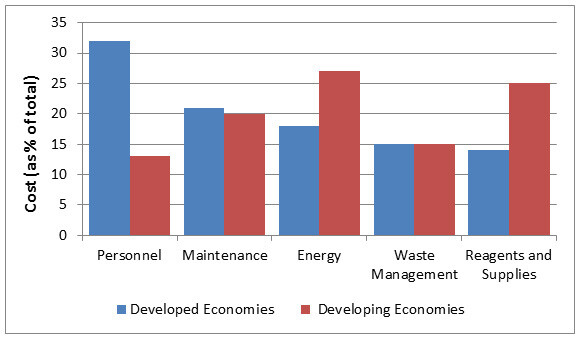

The primary disadvantage of the highly effective aerobic treatment system is the high costs associated with system operation and maintenance. The system requires constant aeration due to the high oxygen demand of the quickly multiplying bacteria and the decomposing organic matter. It also requires careful monitoring and mechanical mixing to enable optimal bacterial growth. These factors result in the process being manpower and energy intensive. A breakdown of typical recurring operational costs of a biological wastewater treatment facility in both developed and developing economies is shown in Figure 1. The highest expenditure for wastewater treatment facilities in developed countries is on personnel, while it is on energy in developing countries.

ECONOMIC ANALYSIS OF ALGAE WASTEWATER SYSTEMS

Aerobic bacteria and algae can be paired to create a self-sufficient wastewater treatment system. In an algal-bacterial system, carbon-dioxide produced by aerobic bacteria — the by-product of its action on sewage — is freely utilised by algae to facilitate growth. The algae in turn release oxygen into the system, creating a mutually beneficial cycle of growth. This symbiotic relationship exists in nature and has been utilized for the treatment of weak wastewater, but its commercial applicability and scalability have been explored only in the last 50 years.

Figure 1. Breakdown of Recurring Operational Costs in a Biological Wastewater Treatment Facility, Global, 2014

Algal-bacterial systems have demonstrated the ability to treat a wide variety of wastewater including human sewage, livestock waste, agricultural waste, and industrial waste containing metal residues. This system can bring about savings in the form of reduced energy expenditure for oxidation and nutrient removal, and produce residual biomass with high monetary value. Pilot studies have shown a reduction in energy expenditure to about half of the current rate (0.66 MWh electricity per million litres treated) and have produced nearly 6,000 litres of algal bio-crude oil per acre of the treatment facility. Despite holding a lot of promise, high capital costs associated with specialized treatment plant setup, low-lipid content of current algae strains, and low-efficiency of biofuel extraction techniques have held back the adoption of algal-bacterial systems. The algal biomass cannot be used for food-grade products either, and the treatment facility incurs additional costs for its disposal.

Much of this is changing with research in algal biofuels progressing at a quick pace. Biofuel research in the last decade by the US Department of Energy, the National Alliance for Advanced Biofuels and Bioproducts (NAABB), and other top research institutions has resulted in a steep reduction in the cost of production of bio-crude oil — from US$ 13 per litre in the 1990s to a mere US$ 2 per litre in 2014. Improvements to cultivation methods and the use of novel growth mediums have helped decrease the manpower and energy requirements by over 30%. Additionally, with the proper implementation of newly discovered high-lipid strains of algae and high-yield hydrothermal extraction methods, the price of algal bio-crude is expected to decrease further. Optimistic predictions of the NAABB indicate that the production cost could fall to below US$ 1 per litre in the next decade. The realization of this goal will set new standards for the wastewater industry and spur widespread adoption of algal wastewater treatment methods.

Clearly, the economic viability of bioproduct and biofuel production methods holds the key to the success of algae-based systems. Countries with aggressive biofuel blending mandates — the United States, European Union member states, India, and China — are heading research and commercialization efforts. The United States, which has been the leader in algae-based technologies for several decades, has provided consistent funding and stimulus for industry growth. The NAABB has partnered with research institutions in India, China, Taiwan, and South Korea, where the climate and environmental conditions are ideal for algae production. Research and commercial trials also are being conducted in Israel, Australia, and some European countries. The success of small-scale commercial trials by the US-based OriginOil, Inc. and the Israeli start-up Aquanos is promising. With continued funding and interest, the large-scale commercialization of this technology and wider biofuel use by 2025 is an achievable target.