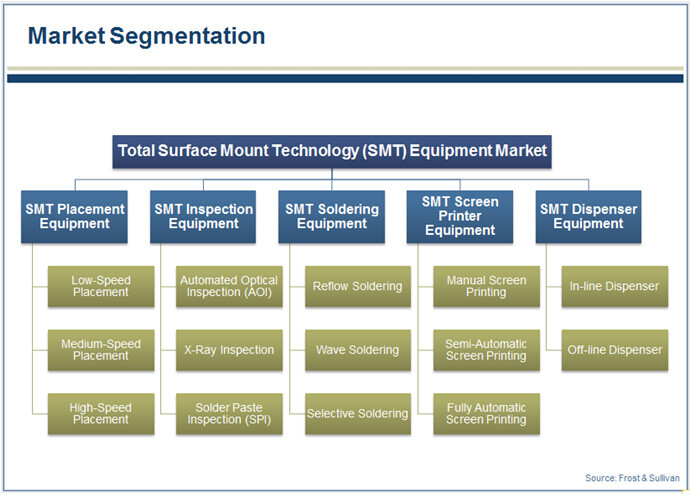

In this digital era, electronic devices have penetrated into various industries and applications from smartphones to industrial electronics to defense electronic devices. These electronic devices come in various shapes, forms, and sizes and are developed according to the application requirement. Thus, the processing life cycle of an electronic device travels through the entire surface mount technology (SMT) equipment from being a printed circuit board to a finished electronic device. The total market is mainly segmented according to the type of SMT equipment and further sub-segmented based on the technology as shown in the chart below.

The electronic manufacturing service (EMS) providers are increasing the number of SMT equipment product lines in order to meet the increasing demand from customers across different industry verticals, and this has bolstered the growth of SMT equipment. In addition, many original design manufacturers (ODM) have also started manufacturing plants, rather than just designing equipment, in order to overcome the increasing competition from EMS providers. Digitization of consumer electronics, especially the penetration of smartphones, tablets, wearable devices, and supercomputers, has drastically increased the growth of this market. The automotive and biomedical industries are showing increased penetration of digitalization and this has a positive impact on the SMT equipment market. Furthermore, there is an increased demand for integrated solutions as a result of a trend shift towards fully automated control solutions. Therefore, customers are shifting from using individual SMT machines to integrated one-stop SMT machines for manufacturing purposes to overcome competition. This trend has resulted in the increased sale of SMT equipment.Consumer electronics is experiencing a transition from manual, analog systems to digitized and automated control systems with more technological advancements. With the increased usage of smart portable devices and introduction of wearable devices, there is a heavy size constraint for both electronic devices and printed circuit boards (PCBs) that are placed in these devices. Thus, continuous innovations in the field of electronics with numerous miniaturized equipment on board lead to a complex PCB design. This trend is expected to increase the demand for efficient SMT equipment in the future. This could give a first-mover advantage to a manufacturer who can invest in new SMT equipment that supports new miniature size. Feeder technology, flexible gantry, and high-accuracy optical encoder system are the examples of product innovations as a result of technological advancements.

The electronic manufacturing service (EMS) providers are increasing the number of SMT equipment product lines in order to meet the increasing demand from customers across different industry verticals, and this has bolstered the growth of SMT equipment. In addition, many original design manufacturers (ODM) have also started manufacturing plants, rather than just designing equipment, in order to overcome the increasing competition from EMS providers. Digitization of consumer electronics, especially the penetration of smartphones, tablets, wearable devices, and supercomputers, has drastically increased the growth of this market. The automotive and biomedical industries are showing increased penetration of digitalization and this has a positive impact on the SMT equipment market. Furthermore, there is an increased demand for integrated solutions as a result of a trend shift towards fully automated control solutions. Therefore, customers are shifting from using individual SMT machines to integrated one-stop SMT machines for manufacturing purposes to overcome competition. This trend has resulted in the increased sale of SMT equipment.Consumer electronics is experiencing a transition from manual, analog systems to digitized and automated control systems with more technological advancements. With the increased usage of smart portable devices and introduction of wearable devices, there is a heavy size constraint for both electronic devices and printed circuit boards (PCBs) that are placed in these devices. Thus, continuous innovations in the field of electronics with numerous miniaturized equipment on board lead to a complex PCB design. This trend is expected to increase the demand for efficient SMT equipment in the future. This could give a first-mover advantage to a manufacturer who can invest in new SMT equipment that supports new miniature size. Feeder technology, flexible gantry, and high-accuracy optical encoder system are the examples of product innovations as a result of technological advancements.

Although there is much digitalization happening across various industries that is boosting the demand for SMT equipment, one of the major restraints in this market is the demand for used SMT equipment. This has been a major constraining factor for various companies in this market and the impact of this factor is a serious concern for companies at present. This is mainly due to the intense competitive structure of the market, which directly forces the manufacturers to cut cost. Significant difference between the cost of new equipment and used equipment has been a major factor that has prompted customers to opt for the latter. This trend has a high impact, particularly in the electronics industry where the small vendors will have a disadvantage in terms of financial capital and purchasing power compared to the tech giants.

SMT equipment plays a central and almost hidden role in the fourth industrial revolution, Internet of Things (IoT), smart environment, and future electronics. SMT is a vital base for the development of the state-of-the-art embedded systems, Cyber-Physical Systems (CPS), global Ethernet networks and IP technology, novel service architectures, and process controllers. The SMT equipment market is expected to witness strong demand and growth opportunity with the introduction of wearable devices, smart factories, and future electronic devices used in IoT.

For any queries related to this article, please contact the author Viswam Sathiyanarayanan at [email protected].